ALPOLIC™ A2

First choice for maximum fire safety: ALPOLIC™ A2

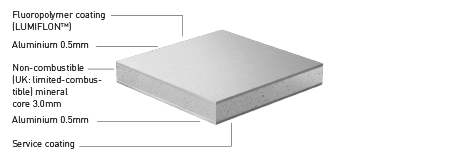

Description

- Technical Data

- Fire classification

| Dimensions | Standard | Unit | Value |

| Total Thickness | – | mm | 4 |

| Cover sheet thickness | – | mm | 0.5 |

| Core thickness | – | mm | 3 |

| Width | – | mm | 1,000 / 1,250 / 1,500 / 1,750 / 2,015 (± 2mm / m) |

| Length | – | mm | max. 7,300 (± 1.0mm / m) |

| Technological Value | |||

| Weigth | – | kg/m2 | 8.4 |

| Tensile strength | ASTM E8 | N/mm2 | 43 |

| 0.2% proof stress | ASTM E8 | N/mm2 | 41 |

| Elongation | ASTM E8 | % | 3.8 |

| Flexural elasticity, E | ASTM D393 | kN/mm2 | 38.5 |

| Deflection temperature | ISO 75-2 | °C | 110 |

| Thermal expansion | ASTM D696 | x 10-6 /°C | 19 |

| Surface | |||

| Coil-Coating | – | – | LUMIFLONTM-based fluoropolymer coating/ reAL Anodised |

| Aluminium alloy | – | – | 3105-H14 / 3005-H14 / 5005A |

| Gloss (measured at 60°) |

EN 13523-2 | % | 15-80 |

| Pencil hardness | – | – | H |

| Country | Test Standard | Results & Classification |

| EU(applicable in Europe, Switzerland and Turkey) | EN 13823, EN ISO 1716, EN 13501-1 | Class A2 – s1, d0 |

| Switzerland | VKF | RF 1 |

| France | – | M 0 |

| Great Britain | BS 476 Part 6 & 7, BS 8414-1, BS 8414-2 | BR 135 |

| Russia | GOST 30244-94 method II, SNIP 21-01-97*,TsNIISK Natural Fire Test | Class G1 “Falme-retardant materials which do not burn without a source of fire.” |

| USA | NFPA (ISAM Test) | passed |