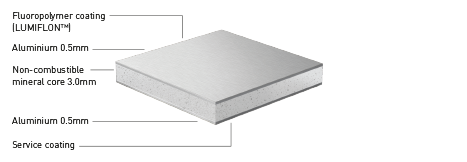

ALPOLIC™ A1

The No. 1 for building projects with the highest fire protection requirements: ALPOLIC™ A1

Description

- Technical Data

- Fire classification

| Dimensions | Standard | Unit | Value |

| Total Thickness | – | mm | 4 (± 0.2mm) |

| Cover sheet thickness | – | mm | 0.5 |

| Core thickness | – | mm | 3 |

| Width | – | mm | 1,270 / 1,575 (± 2mm/m) |

| Length | – | mm | 1,800 – 7,200 (± 1mm/m) |

| Bow tolerance | – | mm |

max. 0.5% (5mm/m) |

| Squareness tolerance |

– | mm | max. 5 |

| Tecnological Value | |||

| Weight | – | kg/m2 | 8.6 |

| Specific gravity | – | 2.15 | |

| Tensile strength | ASTM E8 | N/mm2 | 48.2 |

| 0.2 % proof stress | ASTM E8 | N/mm2 | 46.5 |

| Elongation | ASTM E8 | % | 2.7 |

| flexural elasticity, E | ASTM D7250 | kN/mm2 | 45.6 |

| Deflection temperature |

ISO 75-2 | °C | 115 |

| Thermal expansion | ASTM D696 | 10-6/°C | 20.6 |

| Thermal expansion |

Calculated Value |

W/m-K | 0.4 |

| Acoustical Properties | |||

| Sound Transmission Loss |

ASTM E413 | STC | 27 |

| Surfaces | |||

| Coil-Coating Laquering | – | – | LUMIFLON™ (FEVE) – based fluoropolymer coating |

| Aluminium alloy | – | – | 3105-H14 |

| Gloss (measured at 60°) | ASTM D523 | % | 15-80 |

| Pencil hardness | ASTM D3363 | – | H |

| Country | Test Standard… | Results & Classification | Remarks |

|

EU |

EN 13501-1 (below tests as required) | Reaction to fire classification: A1 |

|

| EN ISO 1182 | Passed | Core test | |

| EN ISO 1716 | Passed | Heat potential value |

|

| EN 13823 | Passed | Panel test | |

| Australia | AS 1530.1 |

Passed |

Core test |

| AS 1530.3 |

Ignitability Index 0, |

Panel test | |

| Singapore | BS 476 Part 4 | Passed | Core test |